A GOOD QUALITY CHUCK CAN ENSURE THAT ALL LATHES WILL PERFORM BETTER.

The main requirements for a lathe chuck is to securely and safely hold the job in the lathe, be accurate and maintain accuracy over a long time.

Understanding the difference between ultimate cost and immediate price is an important factor in selecting a lathe chuck. A lathe chuck should be selected according to the quality of the important features of GRIP; ACCURACY and WEAR LIFE. High quality of these feature means that the chuck will outlast a low price but low quality chuck many times over meaning much lower ultimate cost.

GRIP The better the grip, the safer is the work environment and the faster the job can be done.

Several factors affect the grip:

- For self/centering chucks the percentage engagement between the scroll and the jaw teeth

- There should be a minimum of 3 jaw teeth engaged on the scroll at any position of the jaws.

Figure 1 SMALL DIAMETER CHUCK SHOWING PITCHES OF EXPOSED SCROLL TOOTH

- The smoothness of finish on the scroll tooth and the jaw teeth can affect the transmission of force. Ground finish is usually much smoother and more accurate than machined finish.

- The grip faces of the jaws have to be properly designed and accurately made for the intended application.

- The RPM of the chuck dramatically affects the grip force exerted on the job. The body material also determines the maximum safe RPM the chuck can turn. Choices are cast iron, SG iron and steel. The recommended safe RPM for lathe chucks is governed by Standards din 6386.1 and VDI3106. Note as a chuck wears or is not correctly maintained, the maximum recommended grip and RPM lessen.

- A lathe chuck must be properly balanced or the grip and RPM is adversely affected.

- Examine the end float of the jaws against the scroll tooth.

ACCURACY

Consider the accuracy the maker claims. Not all chucks have the same run-out accuracy when being operated. Some makes of chucks offer different accuracies for job run-out. A good quality chuck should have a run-out not exceeding 40 microns (0.001”) at any position on the scroll for sizes up to and including 315mm diameter. For 400mm diameter chucks a run-out of .075 microns is permissible. For 500mm or 600mm diameter chucks run-out of 0.10 microns is permissible. If the claimed run-out accuracy is MORE than these values then it is not a precision chuck.

WEAR LIFE & FINISH

The finish of a chuck will give a good indication of the quality. Look for “ground” finish on the chuck body and a blemish-free surface. The life of a chuck is determined by the selection of correct materials, accuracy of manufacture and finish of the various components and how these components work together. Lathe chucks should be regularly cleaned and re-lubricated using grease for the scroll and pinion and oil for the scroll and jaws. NEVER use graphite or graphite-based grease to lubricate a precision chuck, scroll and pinions.

SUMMARY

The following should be checked when selecting a lathe chuck

- The overall finish and how the components work together

- The end float of the jaws

- The exposed Scroll (wind out the jaws) to ensure MINIMUM 3 jaw teeth can be engaged at any one time.

- The percentage engagement between the scroll tooth and jaw teeth

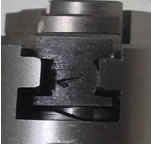

Figure 2 END VIEW OF JAW IN CHUCK BODY SHOWING REAR JAW TOOTH AND START OF SCROLL TOOTH

- For up to 315mm size chuck check if the scroll is hardened and ground.

- Does the maker’s catalogue list the materials used in the various components and the HRC of these components?

- Is the chuck balanced?

- Do the grip faces of the jaw appear to be uniformly made?

- Consider the required RPM in order to select the body material.

- Are spare parts available?

- Does the maker specify accuracy?

ROBINSON INTERNATIONAL PTY LTD